Reviving eMachines Laptop Displays: Niagara's Premier Repair Hub

Niagara's students and remote workers, juggling coursework in St. Catharines or client calls from Thorold, count on affordable eMachines laptops for daily essentials like virtual learning and remote tasks. When a fractured display disrupts your flow, JTG Systems at 577 Niagara Street in Welland delivers over 20 years of specialized know-how to restore functionality quickly. Our no-fix-no-fee guarantee and 90-day warranty provide confidence for community members dealing with these everyday setbacks.

Exploring eMachines Display Structures and Troubleshooting Methods

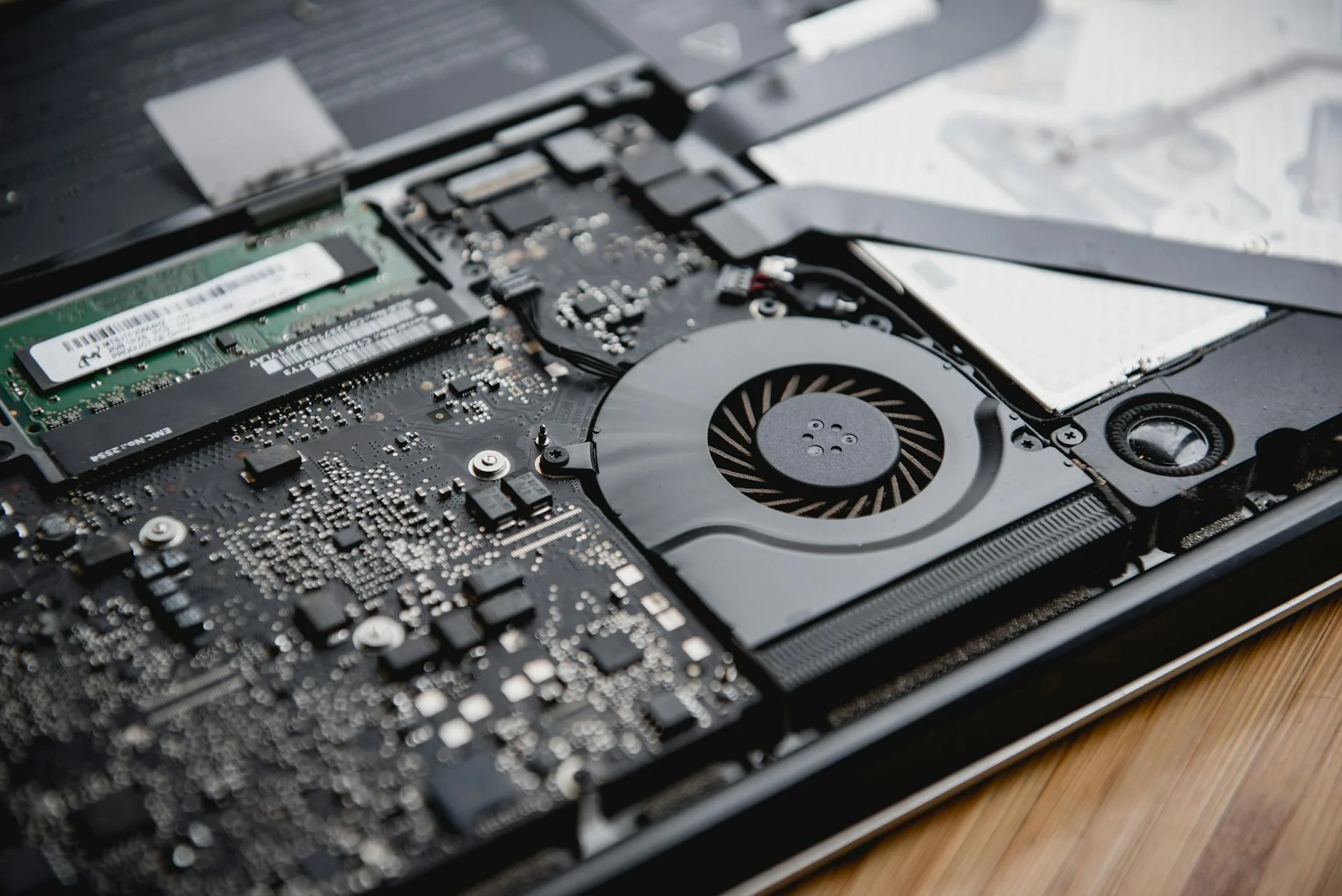

eMachines laptops incorporate cost-effective builds with LCD assemblies connected via delicate flex cables and inverter modules, requiring careful manipulation to avoid further complications. These devices typically employ TN or entry-level IPS screens, vulnerable to physical jolts that can shatter the panel or disrupt illumination systems, a frequent concern for mobile users across Niagara.

Typical Indicators and Weak Spots in eMachines Displays

- Fractured exteriors from accidental falls that scramble the full image.

- Dark patches or pixel failures from compression injuries indicating matrix disruptions.

- Intermittent illumination from inverter malfunctions, common in legacy E510 units.

- Shifted hues due to dislodged LVDS links, frequently confused with graphics faults.

- Total darkness despite active operation, suggesting barrier glass interference.

- Impaired interactive areas in combo units from detached sensing films.

- Vertical streaks from column driver breakdowns in the display core.

- Border light bleeding from damaged perimeter adhesives, worsened by thermal cycles in transit.

- Gradual fading from worn CCFL lamps in older non-LED designs.

- Blurred outputs from liquid damage, common in the region's damp climate.

- Abrupt total failures tied to erratic inverter voltage supply.

- Blurry edges from adhesive breakdown in the chassis during frequent openings.

- Sporadic image halts from flex degradation near pivot points.

- Inconsistent lighting from defective LED arrays in updated models.

- Warped visuals from signal noise affecting driver electronics.

- Color inversion spots from delaminated polarizing layers.

- Response delays in refresh rates from timing controller glitches.

- Overheating traces on panels from poor ventilation in compact eMachines frames.

- Partial illumination from segmented backlight failures.

- Static interference lines from ground loop issues in power delivery.

Our diagnostic process at JTG starts with external examinations and voltage checks using precision tools, progressing to connection adjustments and load testing to isolate problems efficiently, leveraging in-depth familiarity with eMachines layouts.

Why Niagara Residents Rely on JTG Systems for eMachines Display Fixes

As the preferred choice for eMachines screen restorations in the region, we procure high-quality compatible components to ensure seamless integration and durable results.

- Over two decades refining techniques across eMachines D-series to contemporary ET models.

- No-fix-no-fee assurance, meaning zero charges if the display problem persists unresolved.

- 90-day coverage on labor and parts for ongoing reliability.

- More than 1,100 glowing five-star testimonials from local Niagara clients highlighting our dependability.

- Easy access during walk-in times from Monday to Friday, 12PM to 6PM, right in Welland.

- Customized attention for areas like Welland, Thorold, and St. Catharines with a community focus.

- Skilled staff emphasizing secure data practices with protected processing in repairs.

- Transparent pricing that fits the budgets of everyday Niagara households.

- Responsible recycling of outdated displays in line with local eco-guidelines.

- Demonstrated success in reducing interruptions for education and professional demands.

- Advanced testing gear for precise fault identification and reduced revisits.

- Personalized consultations aligning fixes with your eMachines usage patterns.

- Smooth incorporation of firmware enhancements to boost display efficiency afterward.

- Local engagement through complimentary sessions on device upkeep in Welland.

- Adaptable collection services for clients in Thorold and St. Catharines.

- Comprehensive post-service evaluations to confirm peak performance.

- Inventory of ready-to-install panels for eMachines to accelerate resolutions.

- Training in safe handling to prevent future display vulnerabilities.

- Integration with Niagara's tech ecosystem for broader support needs.

- Focus on minimal environmental impact in all repair operations.

Efficient eMachines Display Restoration Workflow and Timeframes

We streamline operations to fit the dynamic schedules of Niagara life, ensuring prompt device recoveries.

Quick Same-Day Resolutions for Simple Display Faults

Suited for superficial breaks or connection slips, these interventions conclude in mere hours. For example, tightening a flex cable on an eMachines E725 revives sharp visuals following a brief validation run.

24-48 Hour Completions for Routine Panel Exchanges

Standard swaps, such as fitting a fresh LED display in G-series variants, finish in this period. We manage takedown, installation, and alignment as you continue your routine.

3-5 Day Durations for Intricate Display Reconstructions

Elaborate scenarios involving bespoke frame adjustments or circuit fixes extend to this range. A case in point is reinforcing the pivot mechanism in a T-series to avert repeated flex strain.

- On-site evaluation right at drop-off for precise estimates.

- Access to on-hand stock for faster component procurement.

- Thorough checks on luminance, hue fidelity, and interaction sensitivity.

- Regular status reports through calls or visits.

- Delivery with operational guidance to enhance display endurance.

- Priority options for pressing situations in the Niagara area.

- Coordination with software tweaks for optimal visual output.

Case Study: Easing a St. Catharines Student's eMachines Display Dilemma

Imagine Alex, a university student in St. Catharines relying on her eMachines for lecture notes and group projects. A slip during a bus ride from Welland led to a spiderweb crack across the screen, obscuring notes and risking assignment delays. Hurrying to JTG Systems, our experts identified a split LCD with preserved core systems, swapping it for a matching replacement while safeguarding her study files. In under 24 hours, Alex returned to Thorold campus with vivid clarity, on track for her semester, courtesy of our neighborhood-responsive expertise.

Your Full eMachines Display Repair Experience at JTG

- Arrival and Initial Evaluation: Deliver your device to 577 Niagara Street, Welland; we review the damage immediately and outline choices clearly.

- In-Depth Fault Analysis: Utilize instruments like signal analyzers to detect display anomalies, probing for hidden flex wear.

- Precise Intervention Implementation: Dismantle methodically, install elements accurately, and adhere to static-free measures.

- Information Security Measures: Identify risks and archive key data prior to hardware interventions.

- Validation and Refinement: Conduct broad tests, including impact assessments for resilience and display parameter adjustments.

- Return and Guidance Session: Provide your laptop with maintenance advice, warranty info, and ongoing support paths.

This structured path prioritizes speed and integrity, maintaining Niagara connections without interruption.

Essential Strategies to Protect Your eMachines Laptop Display

Prolong your screen's vitality using these targeted eMachines recommendations, adapted to Niagara's fluctuating conditions and on-the-go habits.

- Employ padded carriers for journeys across Welland and St. Catharines to buffer impacts.

- Steer clear of harsh climates; avoid vehicle storage in winter chills.

- Install protective films to resist abrasions while preserving view quality.

- Wipe softly using lint-free fabrics to eliminate residues without panel stress.

- Refresh system software from official sources to enhance display energy control.

- Latch the cover uniformly to minimize internal link abrasion.

- Connect peripheral screens at fixed stations to decrease lid manipulations.

- Book routine inspections at JTG to spot early illumination decline.

- Activate dynamic lighting to harmonize operation and reduce wear.

- Adopt remote storage routines for swift incident recovery.

- Block intense sunlight to inhibit thermal distortions.

- Treat access zones tenderly to safeguard flex interfaces.

- Assess pivot smoothness periodically to detect play promptly.

- Adjust hues routinely for steady rendering in visual work.

- Add liquid-barrier shields for defense in Niagara's wet periods.

- Limit direct pressure on the lid during transport.

- Monitor usage temperatures to prevent overheating effects.

- Secure cables internally during any self-maintenance.

- Utilize stands for elevated viewing to ease hinge load.

- Enable power-saving modes for prolonged battery-display synergy.

Prepare to Restore Your eMachines Display? Reach JTG Systems Now

Prevent a faulty screen from pausing your eMachines in Niagara. Stop by for drop-ins at

577 Niagara Street, Welland, Ontario Monday-Friday 12PM-6PM, or dial (905) 892-4555 for professional input. Our commitments deliver trusted, area-oriented supportâresume your activities without delay.