eMachines Laptop Displays Restored for Niagara's Everyday Users

Local professionals in Welland handling inventory tasks and educators in St. Catharines crafting lesson plans rely on eMachines laptops for smooth daily workflows. A damaged screen disrupts these routines, causing frustration amid tight schedules. At JTG Systems, located at 577 Niagara Street in Welland, our over 20 years of specialized expertise ensure quick recoveries. Backed by more than 1,100 five-star reviews from Niagara neighbors, we offer dependable, area-specific solutions that match the region's dynamic lifestyle.

Exploring eMachines Laptop Design and Display Vulnerability Factors

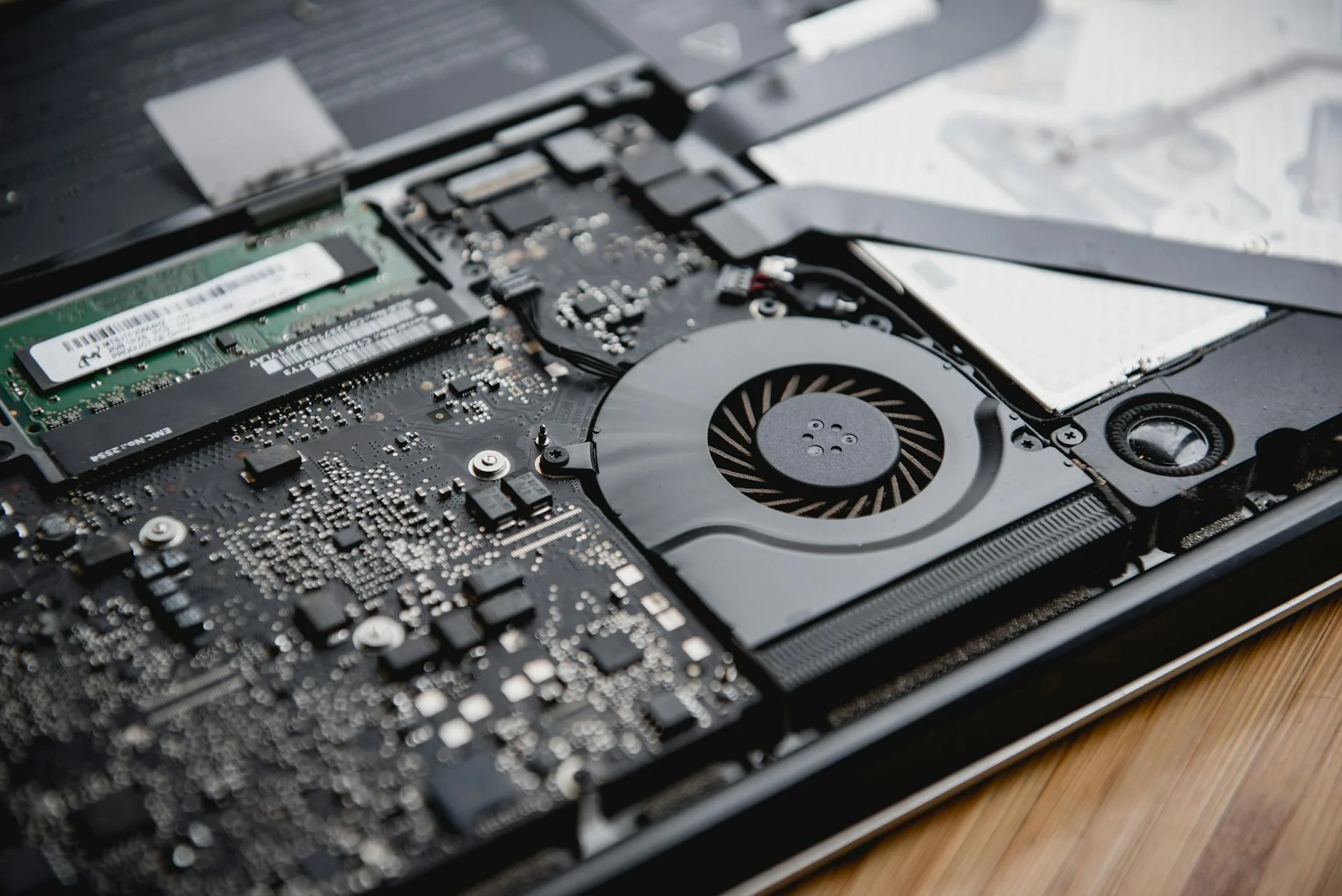

eMachines laptops emphasize affordable builds with dependable routine computing, incorporating slim LED panels within durable, mobile frames suited for travel. However, their lightweight builds and articulated lids frequently result in display problems from ongoing manipulation, causing wiring tension gradually. Our specialists analyze eMachines' illuminated panels, scrutinizing power converters and data links to detect root causes past surface cracks.

Primary Signs and Evaluation Methods for eMachines Screens

- Fractured or Broken Surface: Commonly due to falls on Welland sidewalks, leading to obstructed views across multiple eMachines variants.

- Sporadic Blinking or Streaks: Signals disconnected flex cables or weakening illumination drivers, checked through luminance variation assessments.

- Colored Blotches or Shadow Areas: Arising from jolts or dampness entry, evaluated using uniformity scanning devices to inspect light distribution.

- Total Darkness Despite Device Activity: Points to converter malfunctions or graphics signal faults, verified by connecting to outer monitors in preliminary reviews.

- Altered Hues or Trailing Images: Connected to deteriorating panel layers, located with hue adjustment programs for accurate error spotting.

- Non-Responding Touch on Convertible Units: In touch variants of eMachines, from sensor separation, confirmed via layered component examinations.

- Vertical or Horizontal Stripes: Usually from defective sync processors, recognized with test pattern displays.

- Unexpected Halts: Related to warmth buildup around the panel unit, tracked with temperature cameras for wiring wear.

- Light Leakage Along Borders: Caused by frame shifts, inspected in regulated illumination environments.

- Absent Image Feed: Indicates board-to-panel linkage errors, probed with voltage testers for pathway soundness.

- Dead Pixels in Localized Zones: From precise strikes, charted through thorough pixel analysis procedures.

- Uneven Lighting: Suggests diffuser material flaws, identified with illumination spread testers.

- Panel Distortion: From lid pressure, verified for structure stability in takedown phases.

- Lagged Reaction Speeds: Associated with transmission delays, quantified using response measurement instruments.

- Excessive or Insufficient Brightness: From voltage control errors, adjusted to reference standards.

- Screen Gaps or Seams: Due to adhesive failure in humid Niagara conditions, detected during frame alignment checks.

- Audio-Visual Sync Problems: Linked to integrated cable bundles, tested with multimedia playback diagnostics.

- Overheating Indicators on Panel: From poor ventilation in compact designs, monitored via thermal profiling.

- Color Shift During Angle Changes: Indicating polarization layer damage, assessed with viewing angle simulations.

- Input Lag in Gaming Modes: Tied to refresh rate inconsistencies, measured with frame timing tools.

We utilize eMachines' adaptable structure for focused remedies that maintain full system operation, resilient to Niagara's fluctuating elements like humidity near the canal.

Why Niagara Locals Trust JTG Systems for eMachines Display Services

As a cornerstone repair hub in the Niagara area, JTG Systems excels by obtaining authentic, matching components that integrate perfectly with eMachines setups, upholding any active guarantees. Our more than two decades of service to spots from Welland to St. Catharines cover legacy E-models to current versions with accuracy.

- No-Fix-No-Fee Guarantee: No charges apply until your display works perfectly, offering security for cost-aware households in Thorold.

- 90-Day Coverage on Repairs: Protects the updated panel from issues, building assurance for routine operators in Welland.

- Over 1,100 Five-Star Ratings: Demonstrating our focus on open, superior service that builds loyalty throughout Niagara.

- Easy Access Hours: Available Monday through Friday, 12PM to 6PM at 577 Niagara Street, Welland, ideal for quick visits post local errands.

- Skilled Repair Team: Well-versed in eMachines specifics, attuned to varied demands from Niagara users.

- Clear Cost Breakdowns: Upfront estimates that value your schedule and budget, free of surprises.

- Regional Component Sourcing: Prioritizing rapid access to cut wait times for community members.

- Area-Focused Approach: Customized fixes that grasp Niagara's distinct operational habits.

- Environmentally Aware Practices: Recycling old parts responsibly, aligning with local sustainability efforts.

- Personalized Follow-Up: Post-repair check-ins to confirm satisfaction in your daily use.

Efficient Service Flow and Expected Completion Times

JTG Systems streamlines operations to reduce interruptions for your eMachines laptop, fitting the demanding lives of Niagara workers and learners. We start with a complimentary entry evaluation on site.

Quick Same-Day Handling for Basic Display Corrections

Suited for direct breaks or linkage adjustments, we finish evaluations and fittings in under a day, returning you to activities like reviewing documents from a St. Catharines workspace.

- Swift appearance and operation review: 10-20 minutes.

- Retrieving standard items from stock: Instant for widespread eMachines panels.

- Fitting and initial validation: 45-90 minutes, with positioning verifications.

- Closing client demo: Guarantees approval prior to release.

- Basic cleaning of assembly edges: Prevents dust buildup during install.

24-48 Hour Service for In-Depth Screen Evaluations

For involved cases like illumination swaps, we fast-track your unit, frequently available for collection in Thorold within a day.

- Thorough probe of lighting or linkage concerns: 1-3 hours.

- Acquiring unique elements if needed: Accelerated for prompt delivery.

- Rebuilding and endurance trials: Validates strength under pressure.

- System software tweaks: Refreshes controllers for better output.

- Compatibility scans: Ensures seamless integration with existing setup.

Longer Durations for Scarce Components or Full Assembly Tasks

Older eMachines requiring special hunts may take 3-5 workdays, with regular progress calls.

- Partnering with vendors for outdated panels: 1-3 days preparation.

- Full interior refresh from regional debris in Welland zones: Avoids recurring problems.

- Extensive confirmation loops: Repeated startup checks for steadiness.

- Holistic hardware reviews: Confirms absence of linked component clashes.

- Final performance benchmarking: Aligns with original specs.

Case Study: Helping a Thorold Retailer's eMachines Display Challenge

Consider Mike, a committed retailer in Thorold, whose eMachines laptop display showed dark patches while organizing stock for peak season. With urgent orders from nearby suppliers, the glitch threatened his operations. He visited JTG Systems during a break, where our experts pinpointed a backlight diffuser fault from repeated bag transport on bumpy roads to St. Catharines markets. That same day, we fitted a new unit, optimized lighting uniformity, and returned his deviceâturning a crisis into seamless productivity and enabling focus on business expansion without delays.

Your Complete Path Through eMachines Display Restoration at JTG

Arriving at our Welland facility initiates a careful sequence safeguarding your information and hardware, embodying our commitment to Niagara's dedicated patrons.

- Arrival and Discussion: Welcomed promptly, share your concern as we conduct a gentle inspection and provide clear expense outlines.

- Information Safeguard Step: Prior to opening, we copy key data to protected storage or your chosen online backup to avert any disappearance.

- Accurate Breakdown: Employing static-free implements, we reach the display section, reviewing lid joints and wires for typical mobile wear.

- Part Exchange: Placing the fitting panel, we secure alignment to prevent shifts.

- Assembly and Adjustment: Fastening elements, we adjust intensity, tone balance, and update speeds for peak clarity.

- Validation Phase: Executing tests like flaw detection and warmth modeling to affirm robustness.

- Delivery and Guidance: Provide your laptop with a full summary, usage tips, and our 90-day protection for lasting performance.

- Optional Upgrade Review: Suggest enhancements like protective covers based on your habits.

Essential Advice for Maintaining eMachines Laptop Display Durability

To protect your eMachines against Niagara's changing climate, including mist from the escarpment or showers in Welland, implement these measures for ongoing panel vitality.

- Employ cushioned carriers for movement in St. Catharines congestion, shielding from jolts and moisture.

- Limit lid angles to advised ranges; eMachines joints endure but benefit from careful handling to ease wiring strain.

- Wipe exteriors with soft fabrics alone, avoiding solutions that might erode protective films gradually.

- Refresh display controllers routinely from official portals to boost operation and spot program-related errors soon.

- Book twice-yearly inspections at JTG to catch subtle deterioration, especially for travelers on Thorold to Welland paths.

- Adjust light levels to surroundingsâdimmer in low light to reduce part fatigue, potentially adding up to 25% lifespan.

- Purge airflow paths often to block debris from area industries impacting panel links via excess heat.

- Reduce outer screen connections to cut lid movements, safeguarding inner cabling wholeness.

- Activate rest modes post idleness to block voltage spikes stressing the power unit on boot.

- For interactive models, fit protective films to counter smudges and light abrasions from normal contact.

- Steer from high dampness keeping to avoid condensation in Niagara's shifting weather cycles.

- Hold by the border when cleaning to spread force uniformly and shield delicate borders.

- Watch for initial cues like faint streaks in different illuminations during standard sessions.

- Use power stabilizers for stations in zones with voltage swings close to the river.

- Position steadily on level bases to avoid lopsided frame pressure.

- Avoid direct sun exposure during storage to prevent panel fading over time.

- Calibrate colors monthly for consistent output in varied work environments.

- Secure cables during travel to minimize flexing in portable setups.

- Opt for matte protectors in bright Niagara summers to cut glare issues.

- Monitor battery health as low power can strain display drivers.

- Integrate with JTG's care packages for comprehensive longevity support.

Merging these practices with JTG's upkeep options keeps your eMachines as a reliable ally in Niagara's active landscapes.

Prepare to Revive Your eMachines DisplayâReach JTG Systems Now

Refuse to allow a broken display to pause your eMachines laptopâJTG Systems delivers skilled, straightforward restorations with our no-fix-no-fee commitment and premier community aid. Visit 577 Niagara Street in Welland, Ontario, Monday-Friday 12PM-6PM for drop-offs, or dial (905) 892-4555 for prompt help. Supporting Welland, Thorold, St. Catharines, and greater Niagara, we're ready to restore your connectivity with trust.

JTG Systems577 Niagara Street

Welland, Ontario

(905) 892-4555